PHYSIC HS CUT UP SYSTEM

The Meyn Physic HS cut up system is developed to support the poultry processor in realising the highest possible revenues, and with an unrivalled speed of 7,500 birds per hour, the Physic HS shows an unchallenged performance. This makes any Physic HS cut up line considerable more effective than existing lines.

The Physic HS cut up systems can be configured to match a large number of situation specific requirements regarding product type, quantity, quality and flexibility. The Physic HS system is designed for line speeds ranging from approximately 3,000 to 7,500 birds per hour. Lower product speeds are possible by adapting the shackle pitch.

The Physic HS’ design is practical, simple and open. This allows for easy access during cleaning and maintenance. The system is robust and can effortlessly be operated, due to its limited complexity and the moderate number of moving parts. As in our other equipment, a lot of attention has been given to the Total Cost of Ownership (TCO) indicating that maintenance and spare consumption will be at a minimum.

WING TIP CUTTER

The wing tip cutter separates the wing tips from the rest of the wings with the bird in backwards position.

The amount of wing tip to be taken off is adjustable. The machine can easily be by-passed in case a whole wing cut is required.

MIDDLE WING CUTTER

The middle wing cutter cuts through the second joint of the wing separating the middle wing from the bird. The machine is placed after the wing tip cutter. The middle wing cutter shows a consistent performance within a wide range of product weights.

HY WING CUTTER

The HY wing cutter anatomically removes the (whole) wings from the bird. The HY wing cutter guarantees a highly consistent and precise cut. When required, the cut can include a maximum amount of back meat while minimising the amount of breast meat, but other priorities can be selected as well.

BREAST CAP CUTTER

The breast cap cutter gives an exactly positioned, constant and symmetrical cut. This allows for a maximum of valuable breast meat to be left with the cap while minimising bone contamination of untrimmed filets in the form of ribs. The module can cut the ribs at variable lengths.

FRONT HALF CUTTER

The front half cutter accurately separates the front half from the griller. Similar to the breast cap cutter, this machine is easy to clean. It produces untouched fillet oysters intact, symmetrically and accurately cut.

SADDLE TRIMMER

The saddle trimmer also shares the design features of the breast cap cutter providing constant and exactly positioned cuts. The module cuts the upper back part from the saddle. The trimmed saddle remains in the shackle. The unit is always positioned after the breast cap cutter.

LEG PROCESSOR

The leg processor divides the incoming saddles by separating both legs from the backbone. This results in two anatomical legs that remain in the shackle while the backbones is dropped. Two versions of Physic HS leg processor modules are available.

SADDLE CUTTER

The saddle cutter offers the possibility to produce two different cuts with one machine. Depending on the preference of the customer, the saddle of the bird can be cut symmetrically through the spine to produce two identical leg quarters. Or the spine can be cut from the saddle to produce whole legs without spinal cord.

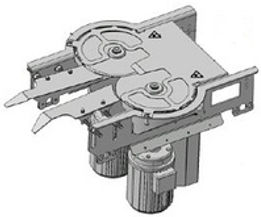

DRUM/THIGH SEPARATOR

The drum/thigh separator is installed in a 180 degrees angle of the overhead conveyor. The module cuts through the joint, producing either a drumstick. and an anatomical thigh or a drumstick and a thigh quarter. Both drums and thighs are fixed during cutting.

WHOLE LEG PRECUTTER

The Meyn whole leg precutter is the solution to automate a critical process step in the whole leg deboning operation. It’s is an added value for those customers who are whole leg deboning manual, as well as automatic with the Meyn WLD M2.0.

TAIL CUTTER

The birds are guided backwards through the tail cutter, with the guides centring the tail on both sides. This allows for a highly precise and controlled tail cut. The amount of tail to be removed can be adjusted to customers’ requirements. This improves yield as undesired loss of excess fat, skin or meat is prevented.